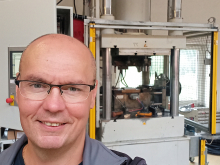

"or what an older top press may look like"

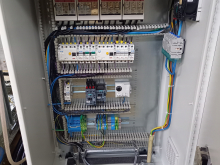

Complete controller exchange included 24 mold heating zones, new cabinets, wirings, cables and servo pump installation

Type: Wickert WKP 2500 S

Clamping force: 2500kN

Year of production: 1999

Location: Germany

Renovation included:

- obsolete Siemens control system exchanged by new Keba controller

- installatin of 24 mold heating zones

- new cabinets, wirings and cables

- Servo pump installation

- Custom application specialized for specific parts and quality control.

- production sequencer for Duroplast production (free programmable machine sequencer)